Imposition Block Repeat Overrides

When quoting on digital presses that use a digital frame, a die will populate the frame based on its ‘block’ configuration. Enforcing the Nup to be die based can result in reduced frame usage and in turn, increased click rate expenses.

As an example, this block is 42up (3 across x 14 around):

Based on the imposition block size, the die can only fit 3up around the

frame causing space to be unused:

When you do not want the block to dictate the printed number around the frame, you can override the configuration using the option to ‘Only Enforce No Across’. This is used in conjunction with the field ‘Impo Block Repeat (Around)’. You can also do the opposite and ‘Only Enforce No Around’.

Only Enforce No Across – This checkbox tells printIQ to ignore the block settings for ‘Depth (Around)’ and only recognise the ‘Width (Across) settings. In this case 3 across.

Only Enforce No Around – This checkbox tells printIQ to ignore the block settings for ‘Width (Across)’ and only recognise the ‘Depth (Around) settings.

Impo Block Repeat (Around) - This field sets the repeat ‘Depth (Around)’ the frame. This will include any required bleed:

This then lets the items around fill the cylinder or digital frame:

Using the above has taken the click count from the original number of 404 to the new number of 333, reducing the costs of the job.

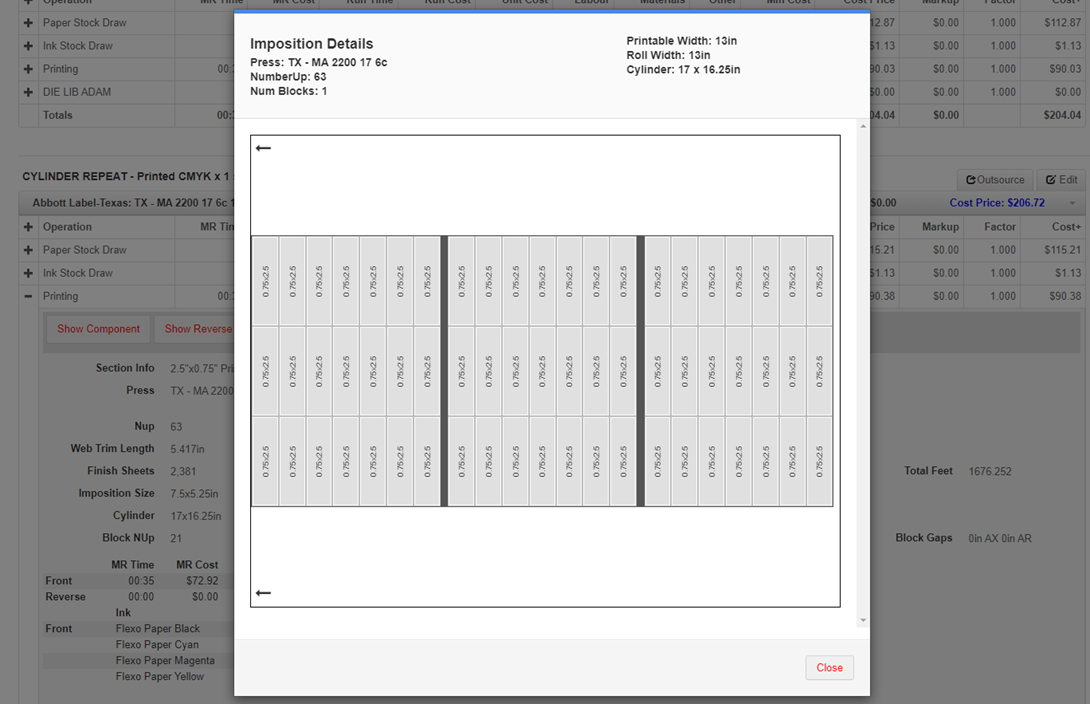

Cylinder Overrides

When a flexographic press has a large number of cylinder options, printIQ will calculate on all configured options to calculate the most cost-effective production path. This can slow down the calculation process as options are included that most likely would never be used due to the inefficient usage around the cylinders.

As an example, the below quote as calculated all the below paths:

The final path chosen as the most cost effective utilises the cylinder

to the maximum: But it has also calculated options with inefficient cylinder usage:

But it has also calculated options with inefficient cylinder usage:

When configuring the die with the standard setup options:

We can add additional configuration by setting a ‘Cylinder Repeat

Length’ and ‘Cylinder Repeat Tolerance’.

This is to enforce that a die is only used on cylinders that can fit a multiple

of a specified length set the Cylinder Repeat Length. The tolerance is how far

out this can be and still be considered a match (leave blank or 0 for exact

only).

Set the repeat length to match that of the block ‘Depth (Around)’ and set a

tolerance:

When calculating the same quote with the cylinder repeat configured, the

paths calculated are greatly reduced and the inefficient layouts are excluded

early in the calculation process:

Only options that fit a multiple around with a max gap between blocks (as

configured in the tolerance) are returned.

This ensures all returned option are efficient in their usage:

Internal Use Only - Settings

‘Eliminate Oversize Roll Sizes with same NUp’

We have a back end setting that will remove larger width rolls from the calculation when the smallest size width with the same number up has been calculated. Again this will reduce the number of paths calculated:

Limit Press Options by Die Library Component

A die can be configured to only quote on selected presses by using the field ‘Imposition Reference’.

This field is found in 2 places, ‘Press Configuration’ and an operation ‘Imposition Requirements’. When these two fields match, the quoted paths will be limited to these matching options.

Example:

We have a quote set to use a selected die:When calculated, all possible production paths are calculated:

When calculated, all possible production paths are calculated:For this die, we only want the presses of OFF -20” and OFF26” to be used in production calculations.

Against each press/option, we use the ‘Imposition References’ field to enter the text ‘Die Group 1’:

For this die, we only want the presses of OFF -20” and OFF26” to be used in production calculations.

Against each press/option, we use the ‘Imposition References’ field to enter the text ‘Die Group 1’:

Multiple references can be linked to a single press

If a press base configuration has a reference, all press options under that base configuration will also get that reference through inheritance.

Inside the die library’s imposition components, under the ‘Production Options’ field, enter the same reference into the ‘Imposition Reference’ field:

Now, when quoting, only presses containing the same imposition reference are calculated against:

Related Articles

Die cutting - creating a die library, or manually entering.

1. Manually Inputting Die Information into a Quote If you do not have a die on file, you may need to manually enter the die information for the block in the quote. You do this by clicking the production method wrench/spanner for the section * Turn on ...

OPERATIONS - Die Library Setup

Setup process First we create a die library operation as a ‘Section’ type operation. This allows us to apply the die at the section level: DIE CYL Rectangle – Cylinder Rectangles Then inside the operation's detail screen, I can use two fields to add ...

Die and Product Tweaks - CUSTOM QUOTES – Quote by ‘Die Library

The Die In market segments such as label printing, the die is the basis of the job. With this in mind, you can configure a custom template to prioritize the die as the starting point for the quote. Against a custom template, on the admin screen, at a ...

Die-Based Quoting

Custom Quotes – Quote by ‘Die Library’ In market segments such as label printing, the die is the basis of the job. With this in mind, you can configure a custom template to prioritise the die as the starting point for the quote. Against a custom ...

OPERATIONS - Imposition Override Operation

IMPOSITION OVERRIDE OPERATION The following outlines how to create an operation that will override the number up on a quoted imposition. In this example I have quoted a business card job: When IQ has calculated the imposition, it has imposed ...